WE MANUFACTURERING

INSPECTION & TESTING

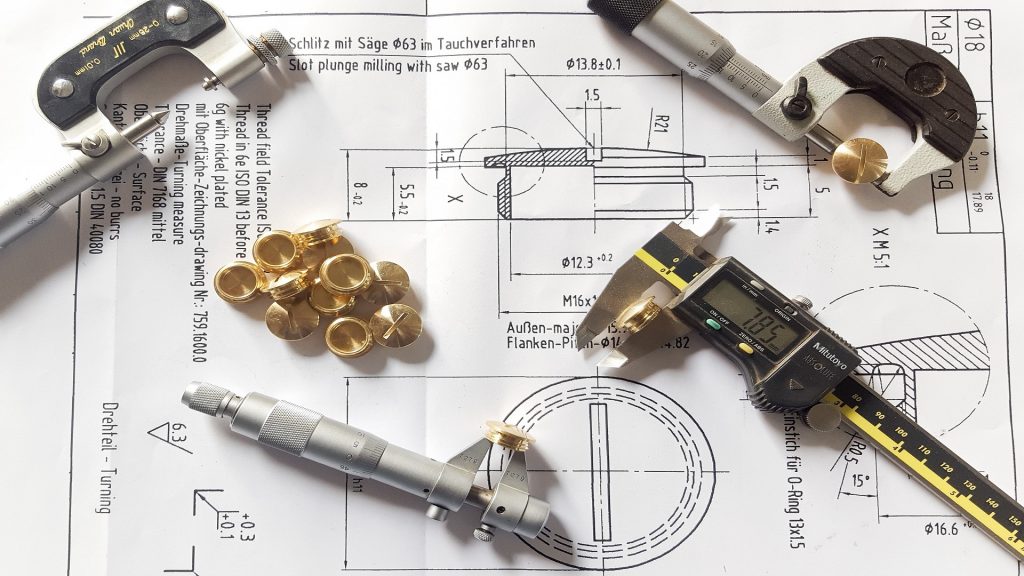

At Airgrip we follows varies quality check at every stage of manufacturer process and 100% visual inspection befour dispatch to ensure that near zero defect Brass turned components and cable gland parts supplied to our Customers.

We continuously developing and upgrading our machine, mechanism, fixtures and system for minimizing the human making error To support our near zero defect Brass Precision Machined component manufacturing philosophy.

We continuously upgrading and updating our instruments as per latest trend and Brass Custom Turned Parts and Custom Brass Fittings requirement to assure supply of best quality products.

( Quality you can Measure)

Measuring and Testing facility in-house and out side lab

* Vision inspection system

* Plating Thickness Testing Machine

* Spectro analysis

* Surface finish testing machine

* Digital Vernier Caliper

* Micro Meter

* Thread Pitch Micro Meter

* Inside Micro Meter

* Ring & Plug Gauges for various Threads

* Plain Plug & Ring Gauges

* Special Structural Gauges to Control Critical Dimensions

* Pressure Testing Rig

* Hardness Tester

* Elongation test

* Magnetic Comparator Stands

* Magnifying Lenses

* Surface Plate

Request a Call Back